RUBBER MOULDING COMPOUNDS

The compounds can be made:

- of all types of rubber currently available on the market (natural, synthetic or in different combinations)

- of butyl

- for ebonite

- black or coloured (RAL)

- accelerated or non accelerated

- hardness: 18 to 95 Shore

Not only do the sectors of use and any further processes the compounds may have to undergo after being delivered to the customers determine their intrinsic characteristics, but also in which form they are consigned, i.e.:

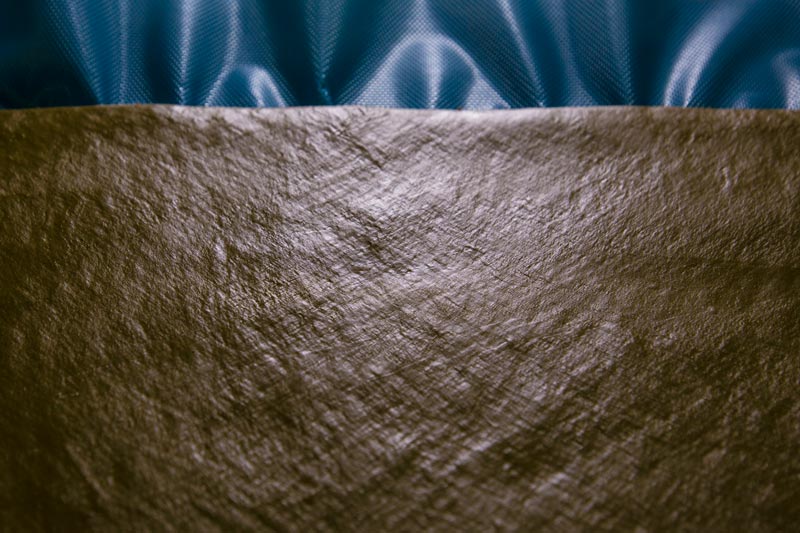

- slabs (thickness from 2 mm onwards)

- extruded (with the aid of specific technology)

- in continuous strips (for injection moulding)

Prior to delivery, all the compounds are packed in polyethylene and (when required) are treated with special talcum to protect them from knocks and moisture.

They are also sent with a specific “identity document” – rheometric curves and laboratory test reports – providing the moulder with the comprehensive information about the material (hardness and curing time/thickness/temperature) required in order to proceed with other processes.